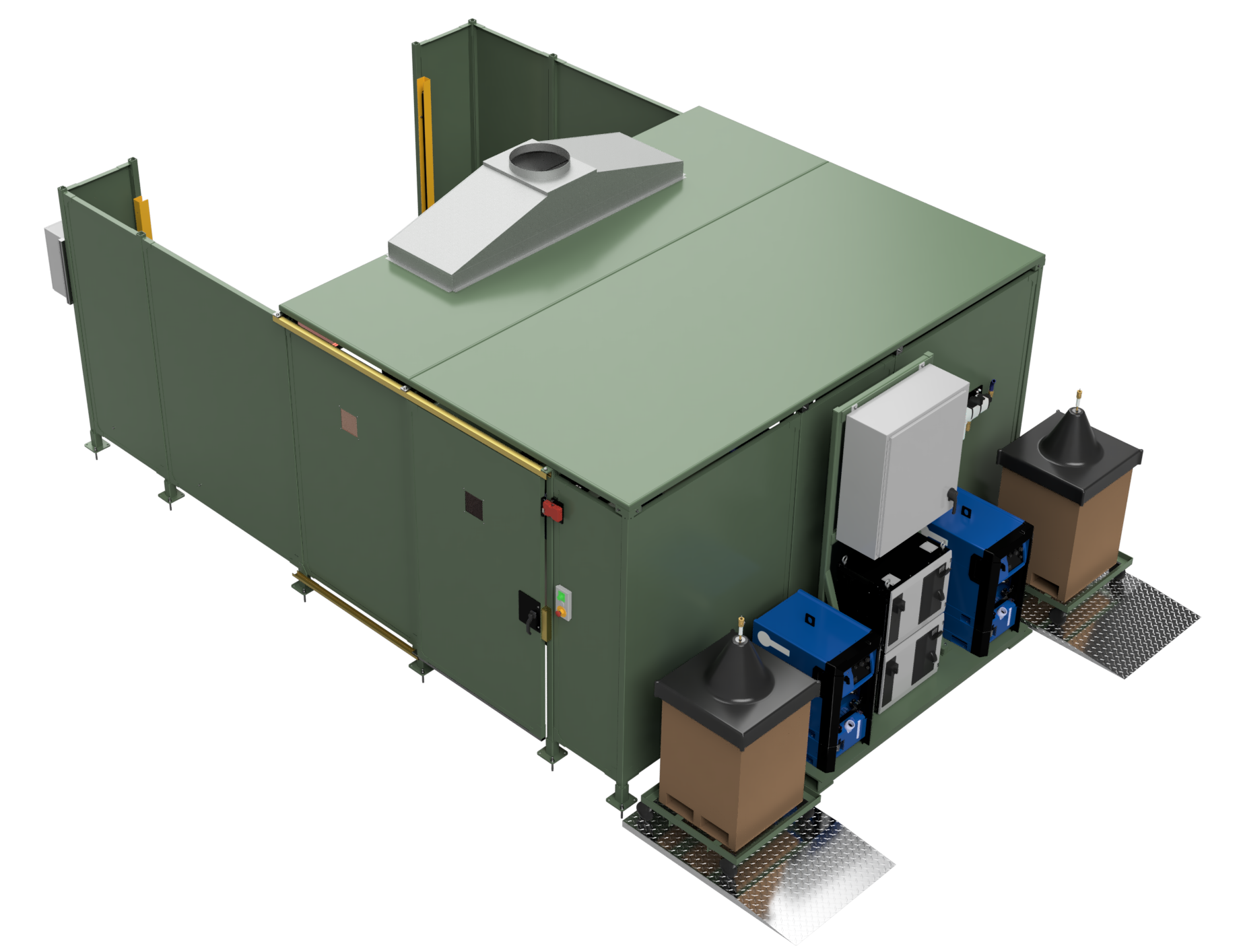

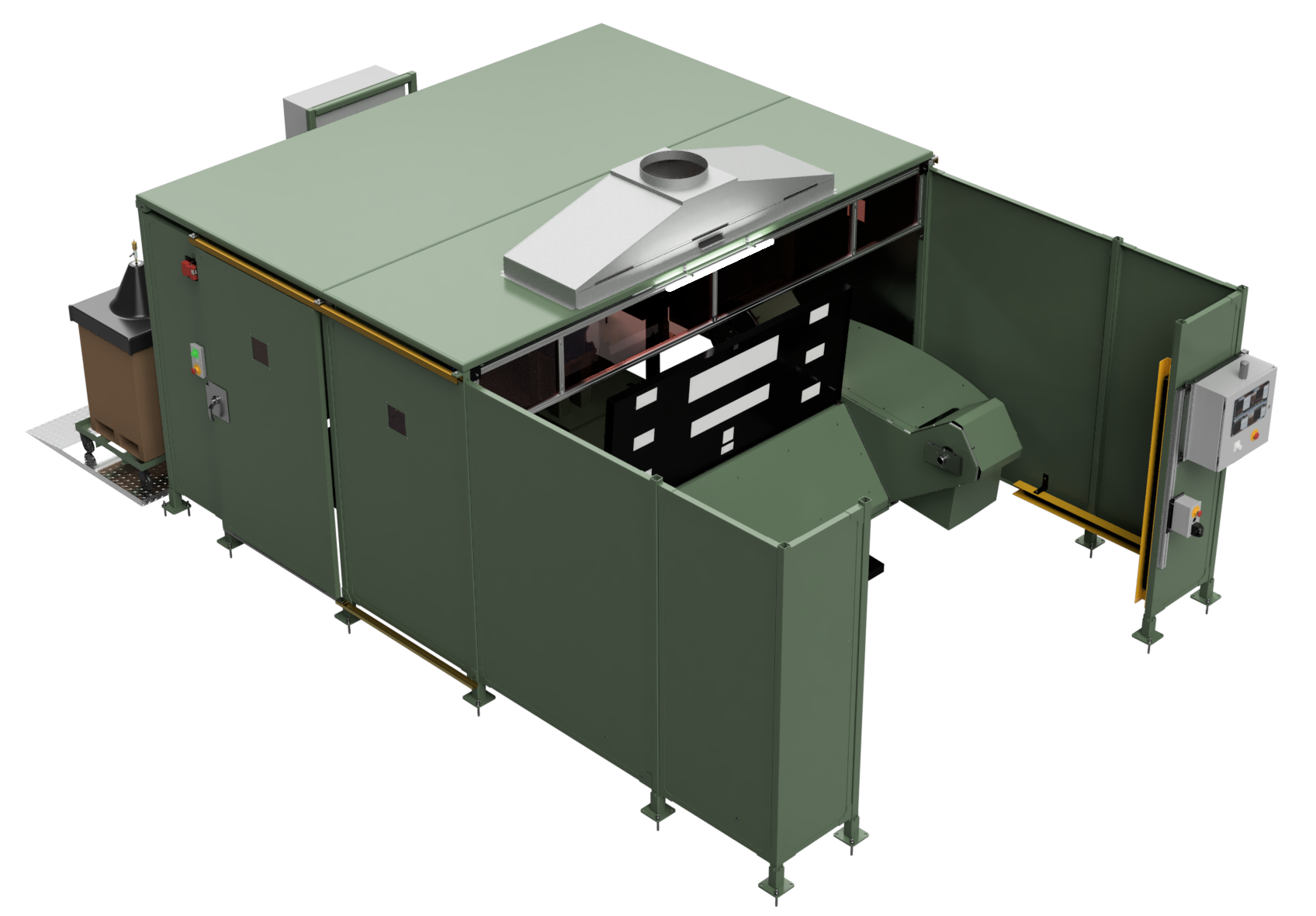

The AMS 2-Station H-Frame Weld Cell is a fully automated welding solution

designed to maximize efficiency and minimize downtime. Featuring a rotating

indexing table with a headstock positioner at each station, this system allows for

the parts to be oriented at different angles to have welding on different sides of

the parts and at the optimum weld angle. The cell features continuous operation

—while the robot welds on one side, the operator can simultaneously load and

unload parts on the other. This parallel workflow significantly boosts throughput

and productivity

Key Features & Components:

- This turnkey welding cell is built for durability, precision, and ease of operation. It includes:

- Heavy-duty welded steel platform base with forklift pockets for mobility

- Rotating indexing dial table for seamless part positioning

- Headstock Positioners

- Two or three robotic MIG welders for high-precision welding

- Weld power supplies & torches for reliable performance

- Nozzle cleaners to maintain torch efficiency

- Two custom tooling fixtures with pneumatic power clamps and part presence sensors

- Enclosed painted sheet metal weld booth with an exhaust hood for safety and air quality

- Safety interlocked doors to ensure operator protection

- Integrated work lights for better visibility

- Advanced electrical control system for seamless operation

Precision-Engineered Tooling Fixtures

Each MIG weld fixture is designed for high repeatability and precise welding. Features include:

- Cast aluminum base plates for durability

- Hardened tool steel, Ampco, or Elkonite locator pins for accurate positioning

- NAAMS-style tooling components, including clamp fingers, net pads, and tooling nests

- Pneumatic power clamps with part presence sensors to verify proper positioning before welding

- X-Y-Z adjustability via NAAMS shims for precise alignment

- Proximity switches for stroke sensing on all pneumatic clamp motions

The system is powered by a Programmable Logic Controller (PLC) for seamless

machine operation and monitoring. Operators can access:

- Fault diagnostics for quick troubleshooting

- Process parameters to ensure precision

- Maintenance and production counters for tracking efficiency

- Manual control options through an intuitive HMI operator interface

Every AMS robotic weld cell is fully assembled, programmed, and tested in our

facility before shipment. Our team will handle on-site installation and setup,

including:

✔ Reassembling and securing all machine components

✔ Leveling, aligning, and anchoring the equipment

✔ Powering up and running full diagnostics

✔ Fine-tuning robot programming

Some more features that can be included are:

- Wire Mesh Panels with Weld Curtains

- Fume Extraction Equipment

- Wire Detect Sensors

- Part Touch Sensing

- Wire Barrel Carts and Weight Scales

Robotic Welding Partners:

Call AMS today at (440) 878-3711 to learn more about AMS, our history, philosophy and our capabilities.