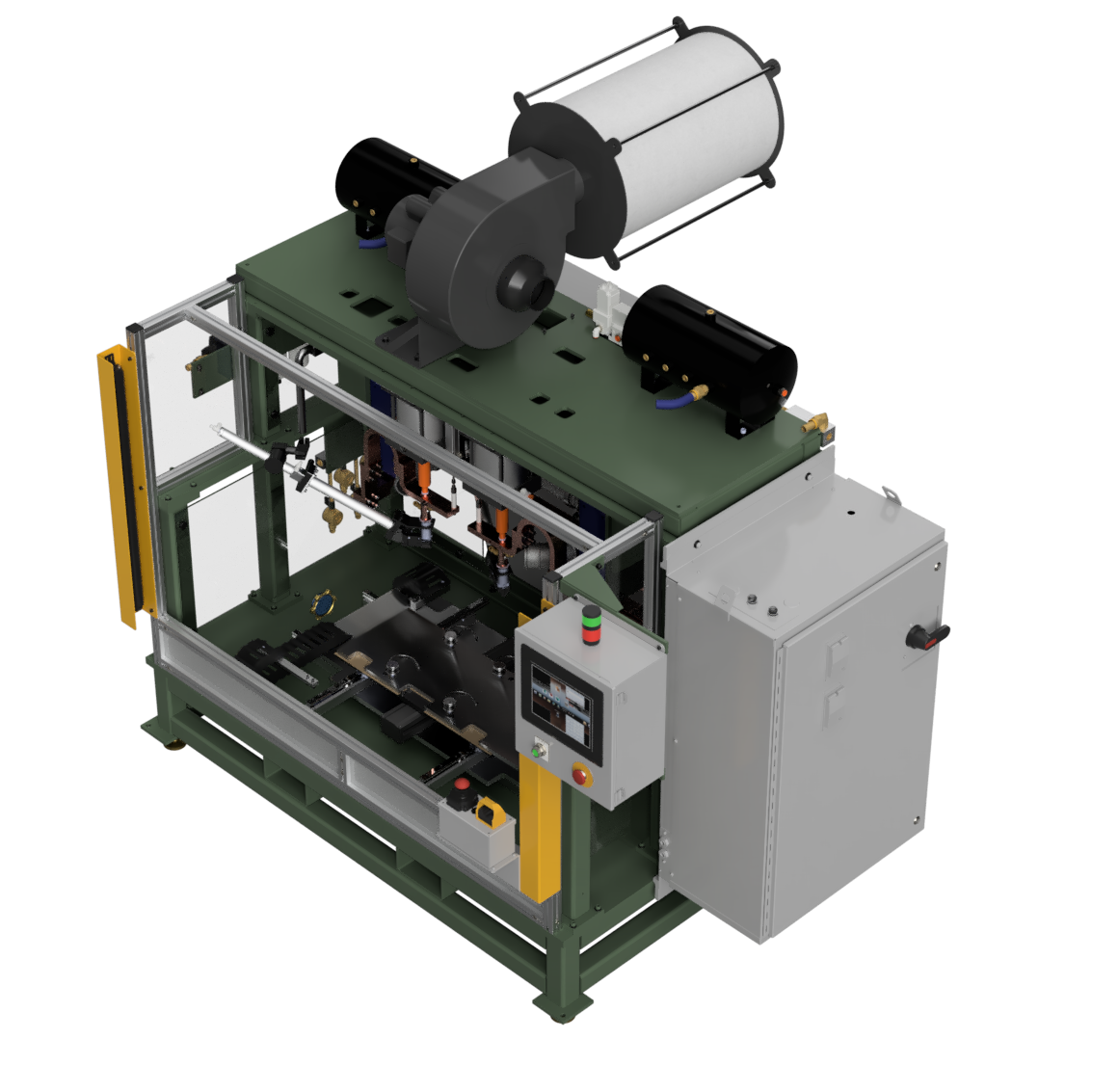

The Dual Gun XY Resistance Welder is a state-of-the-art welding system designed for precision, efficiency, and flexibility. Featuring servo-driven motion in both the X and Y directions, this advanced system enables multiple nuts or fasteners to be automatically fed and welded onto a single part with high accuracy, or multiple resistance welds placed on a part without refixturing the part.

Key Features & Components:

-

This turnkey welding cell is built for durability, precision, and ease of operation. It includes:

- Heavy-duty welded steel platform base with forklift pockets for easy transport

- The servo-driven X and Y motion system allows for accurate positioning and repeatability.

- The lower platen is engineered for quick fixture changeovers and precise location repeatability.

- Fixtures are equipped with fixture identification technology, automatically selecting the appropriate program for each operation.

- Multiple fastener feeders can be integrated, accommodating various part configurations and fastener types.

- Precision Welding Components:

- (2) MFDC machine-type transformers for efficient welding power delivery.

- (2) Weld cylinder with LVDT stroke sensing for precise weld application.

- WTC MFDC W6000 dual weld control ensures optimized weld schedules.

- Integrated Pneumatic & Cooling Systems:

- A cooling water circuit with a water saver valve, strainer, and flow indicators for temperature regulation.

- A pneumatic air supply circuit with an electronic shutoff valve, filter, regulator, pressure gauge, pressure switch, directional valves, and (1) digital pressure regulators for weld cylinders.

Precision-Engineered Tooling Fixtures

AMS welders are designed to maximize accuracy and efficiency in every welding operation. Our tooling fixtures provide:

- Cast aluminum base plates for durability

- Hardened tool steel, Ampco, or Elkonite locator pins for accurate positioning

- NAAMS-style tooling components, including clamp fingers, net pads, and tooling nests

- Pneumatic power clamps with part presence sensors to verify proper positioning before welding

- X-Y-Z adjustability via NAAMS shims for precise alignment

- Proximity switches for stroke sensing on all pneumatic clamp motions

The system is powered by a Programmable Logic Controller (PLC) for seamless

machine operation and monitoring. Operators can access:

- Fault diagnostics for quick troubleshooting

- Process parameters to ensure precision

- Maintenance and production counters for tracking efficiency

- Manual control options through an intuitive HMI operator interface

- Light screen for enhanced safety.

- Light-touch run button for effortless operation.

Every AMS weld cell is fully assembled, programmed, and tested in our facility before shipment. Our team will handle on-site installation and setup, including:

✔ Reassembling and securing all machine components

✔ Leveling, aligning, and anchoring the equipment

✔ Powering up and running full diagnostics

✔ Conducting equipment trials and final testing

✔ Providing operator training and production startup support

Some more features than can be included are:

- Water Chiller

- Multiple Weld Guns

- Poke-Yoke Fixture Integration

Call AMS today at (440) 878-3711 to learn more about AMS, our history, philosophy and our capabilities.