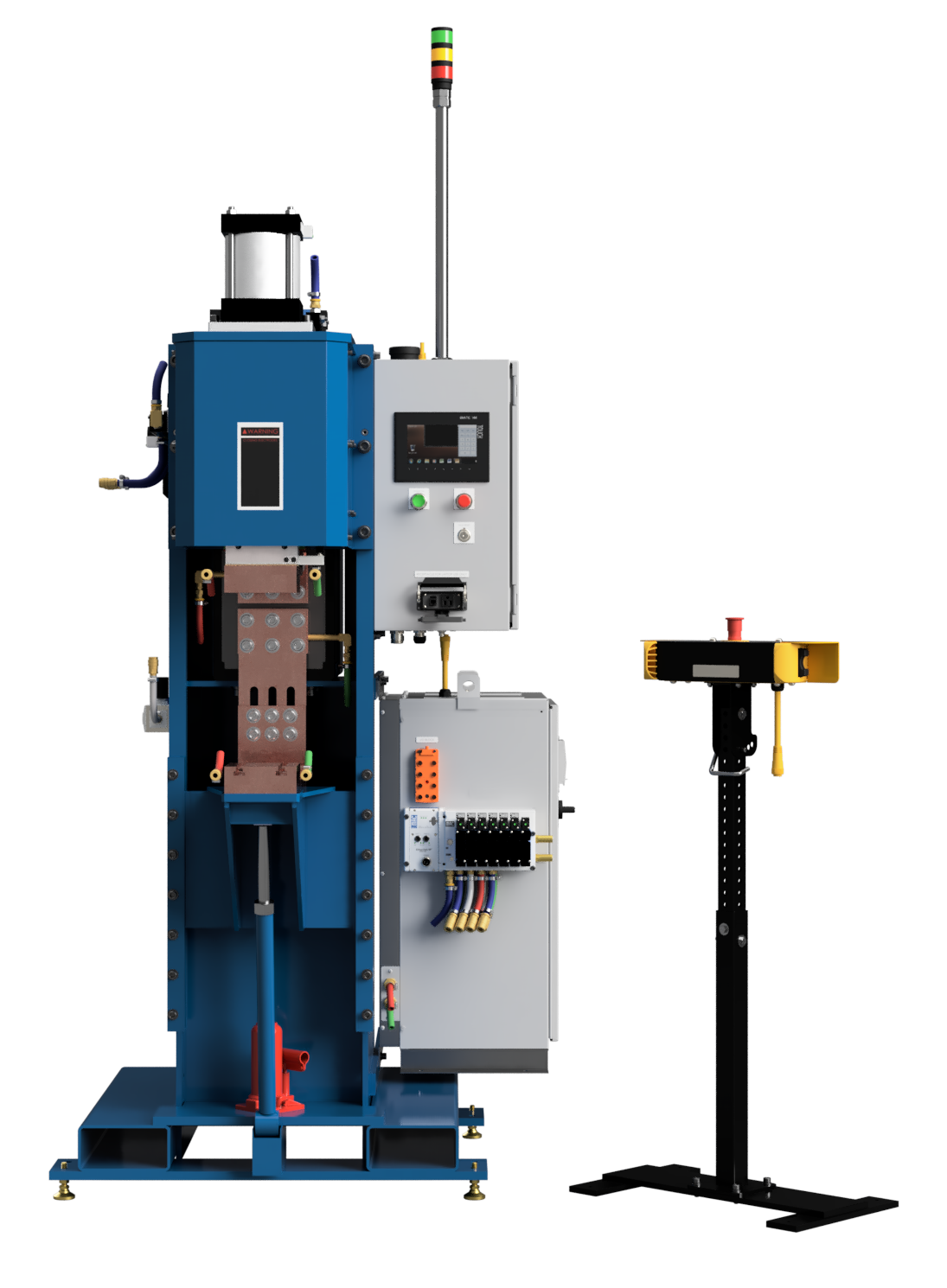

The AMS Size 1 Welder is a versatile welder capable of spot welding 10 Ga material or M4-M10 projection weld nuts or studs. This welder is designed after years of welding applications and experience with the most common single gun welder applications.

Key Features & Components:

-

This turnkey welding cell is built for durability, precision, and ease of operation. It includes:

- Heavy-duty welded steel platform base with forklift pockets for easy transport

- Weld Cylinder – Equipped with a pressure-regulated 6″ bore air cylinder, featuring LVDT stroke monitoring for precise stroke control and repeatability.

- Transformer – High-efficiency Roman transformers for consistent and powerful welding performance.

- Weld Control System – Advanced WTC weld control for precise monitoring and adjustment of welding parameters.

- Adjustable Lower Platen with a manual hydraulic jack

- Cooling System – A dedicated cooling water circuit with a water saver valve, strainer, and flow indicators to maintain optimal temperature and prolong equipment lifespan.

- Pneumatic System – A complete air supply circuit, including an electronic shut-off valve, filter, regulator, pressure gauge, pressure switch, and directional control valves to regulate airflow efficiently.

- Upper and Lower Copper T-Slot plates for fixture mounting

- Main Control Panel – Houses all electrical and control components, ensuring seamless operation and easy access.

- Two-hand control Palm Buttons

- Valve Manifold for Poke-yoke fixture and Fixture slide integration

- User Interface – An HMI (Human-Machine Interface) touchscreen with stack light indicators provides real-time process monitoring, diagnostics, and control.

Precision-Engineered Tooling Fixtures

AMS welders are designed to maximize accuracy and efficiency in every welding operation. Our tooling fixtures provide:

- Secure & Repeatable Clamping – Ensures parts are firmly positioned on datum surfaces for consistent weld quality.

- Adjustability – X-Y-Z adjustments are achieved via NAAMS-style shims, allowing for fine-tuning of part positioning.

- Presence Sensing – All parts are verified before welding begins, preventing errors and ensuring process integrity.

The system is powered by a Programmable Logic Controller (PLC) for seamless

machine operation and monitoring. Operators can access:

- Fault diagnostics for quick troubleshooting

- Process parameters to ensure precision

- Maintenance and production counters for tracking efficiency

- Manual control options through an intuitive HMI operator interface

- Light-touch run button for effortless operation.

Every AMS weld cell is fully assembled, programmed, and tested in our facility before shipment. Our team will handle on-site installation and setup, including:

✔ Reassembling and securing all machine components

✔ Leveling, aligning, and anchoring the equipment

✔ Powering up and running full diagnostics

✔ Conducting equipment trials and final testing

✔ Providing operator training and production startup support

Some more features that can be included are:

- Water Chiller

- Poke-Yoke Fixture Integration

Call AMS today at (440) 878-3711 to learn more about AMS, our history, philosophy and our capabilities.